Skip to content

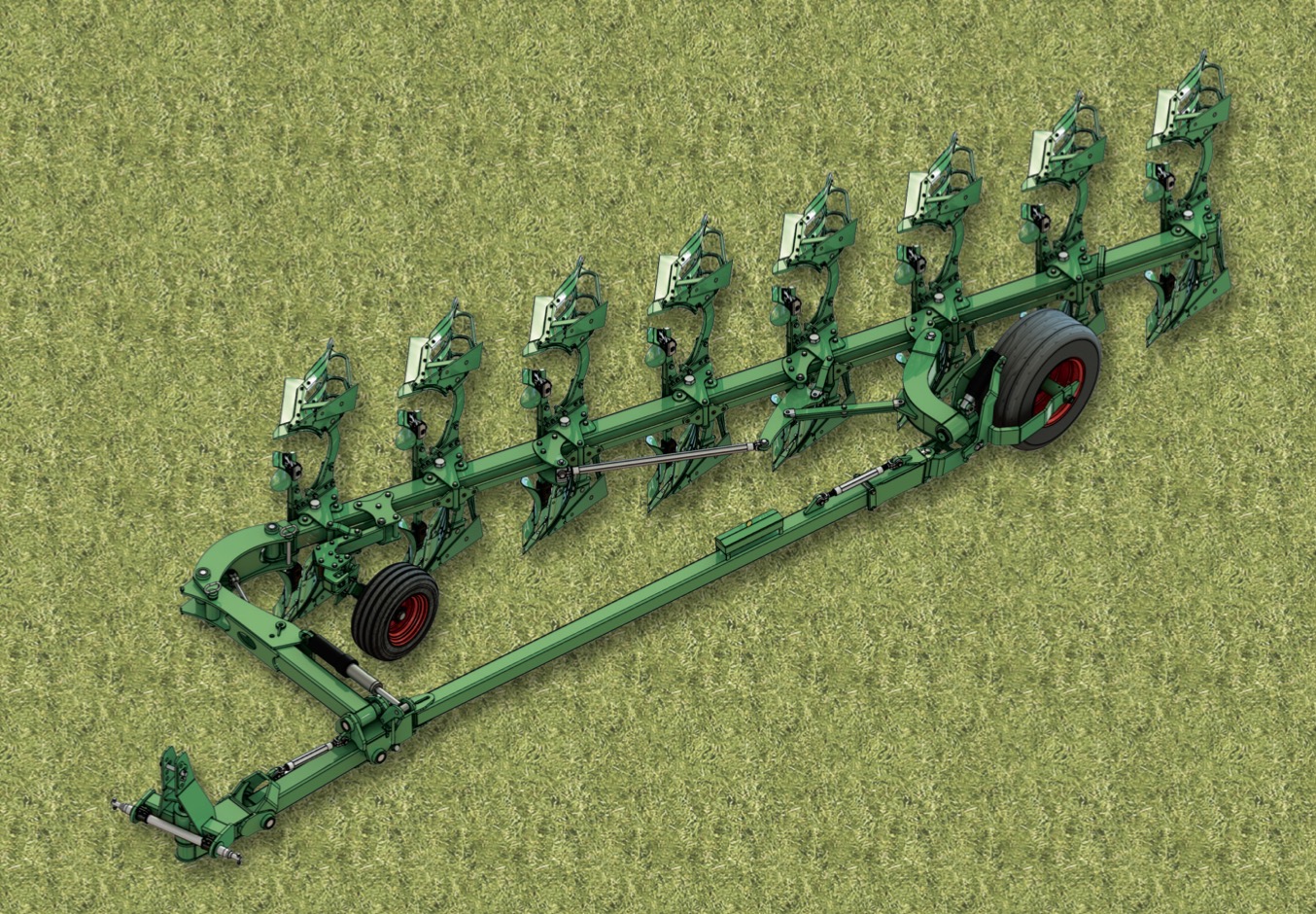

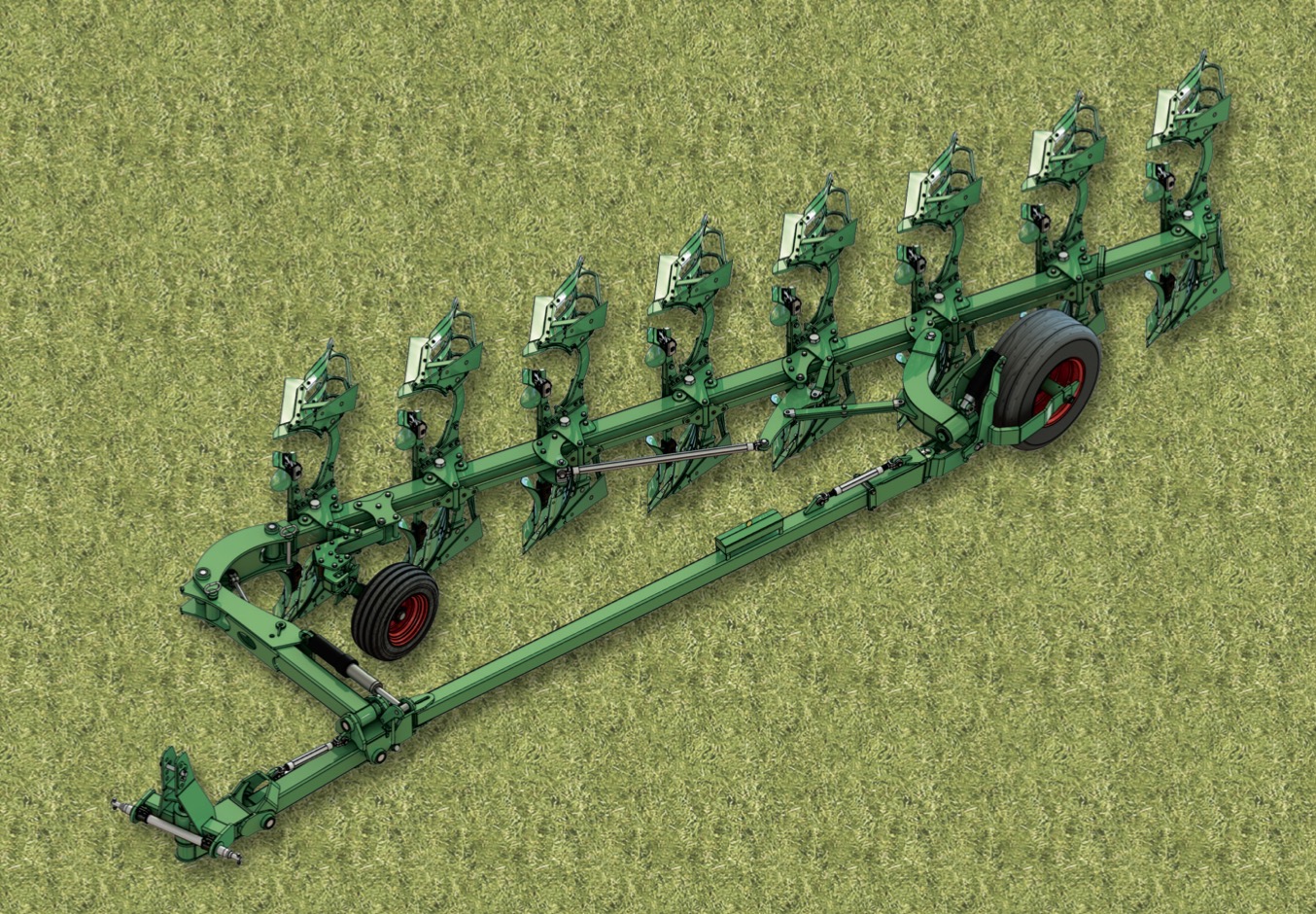

Better stability and wider operating width, higher working efficiency and lower energy consumption for tractors.

THE ADVANTAGE

1.High tensile steel structure ,more reliable and lighter.

2.Advanced heat treatment technology for the parts to be heavy loading especially for the furrow parts, ensure the plough stronger, better impact toughness & more wear resistance.

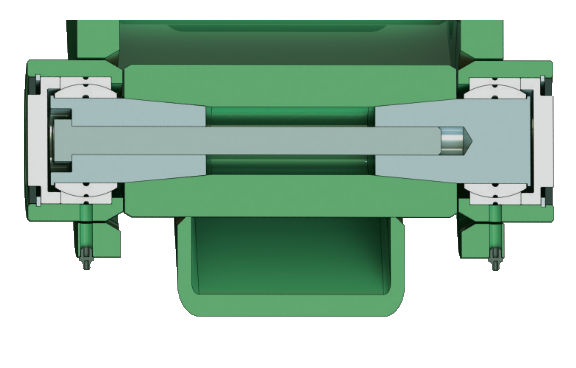

3.Special treated spherical plain bearing with heavy roll extrusion for all main drive shafts, much longer service life and more reliable operation.

4.Automatic hydraulic system with memory cylinders, more reliable and easy to operation.

5.Optional choice: anti-blocking type furrow support without choke by straw or plastic film.

6.Use separate auxiliary furrow and designed with safety shear bolt for overload protection.

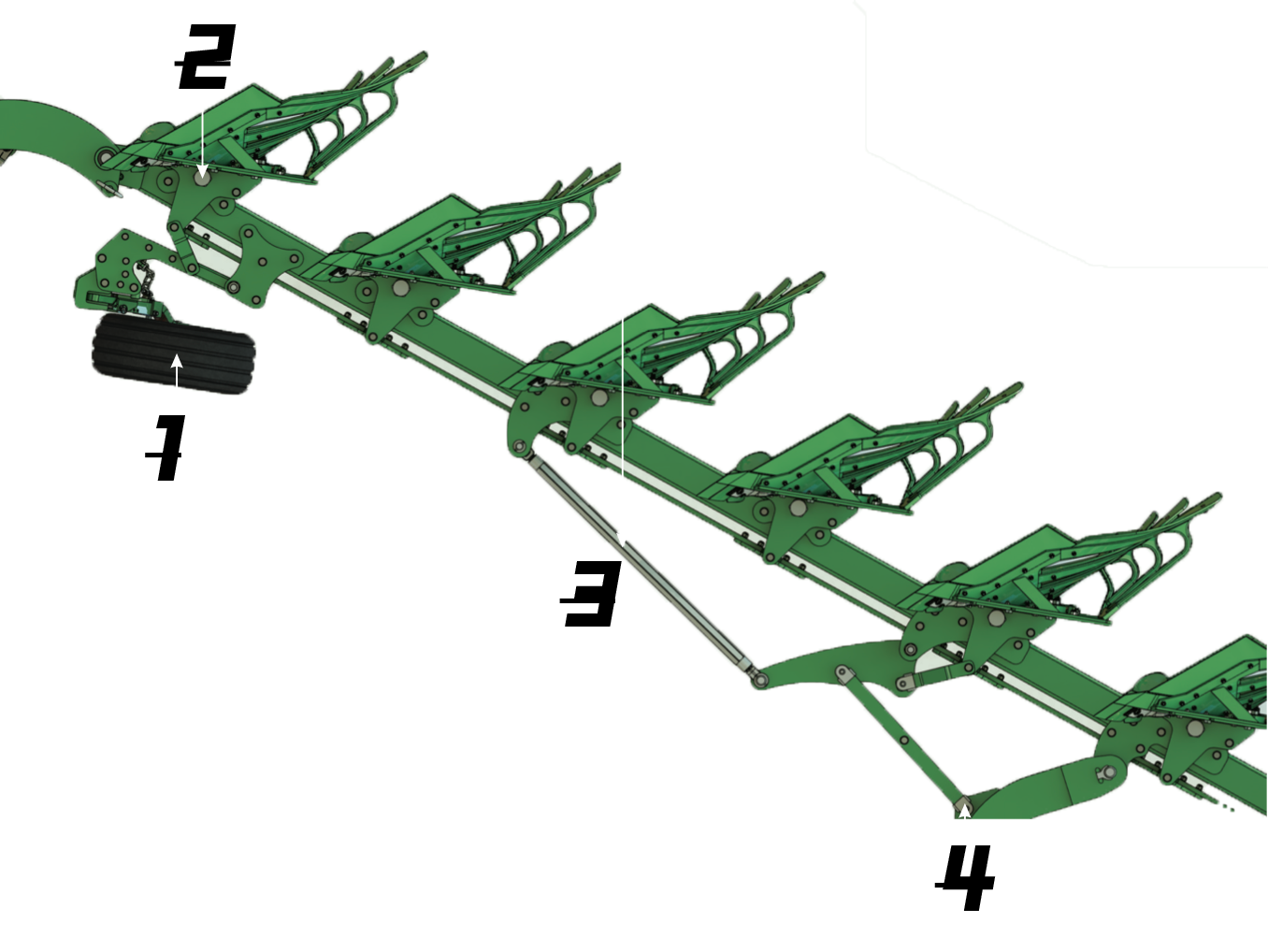

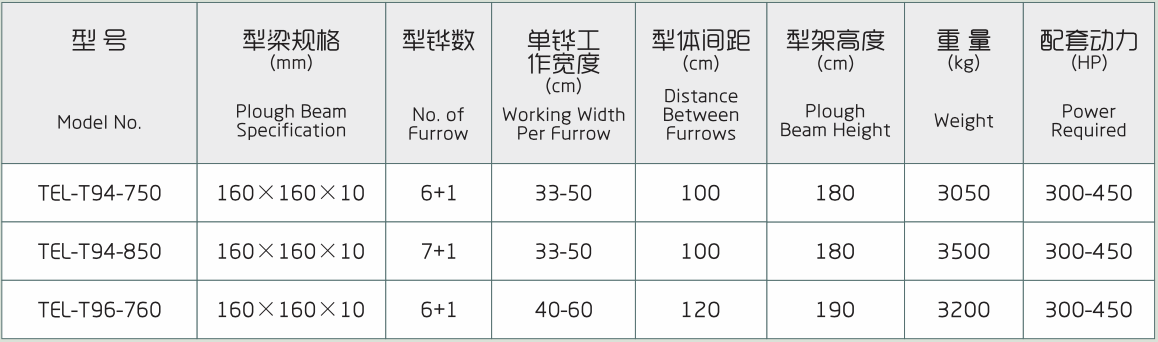

MODEL SPECIFICATION

Note:Slat type option: S type/normal slat; F type/new anti-chocking slat.

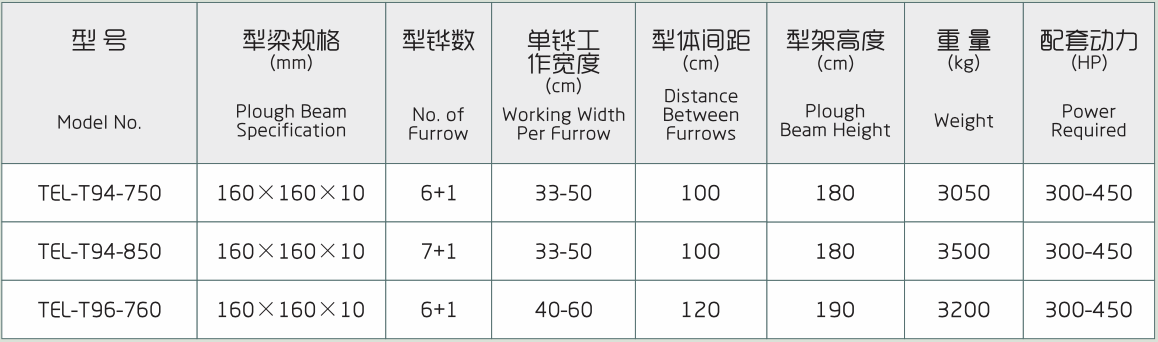

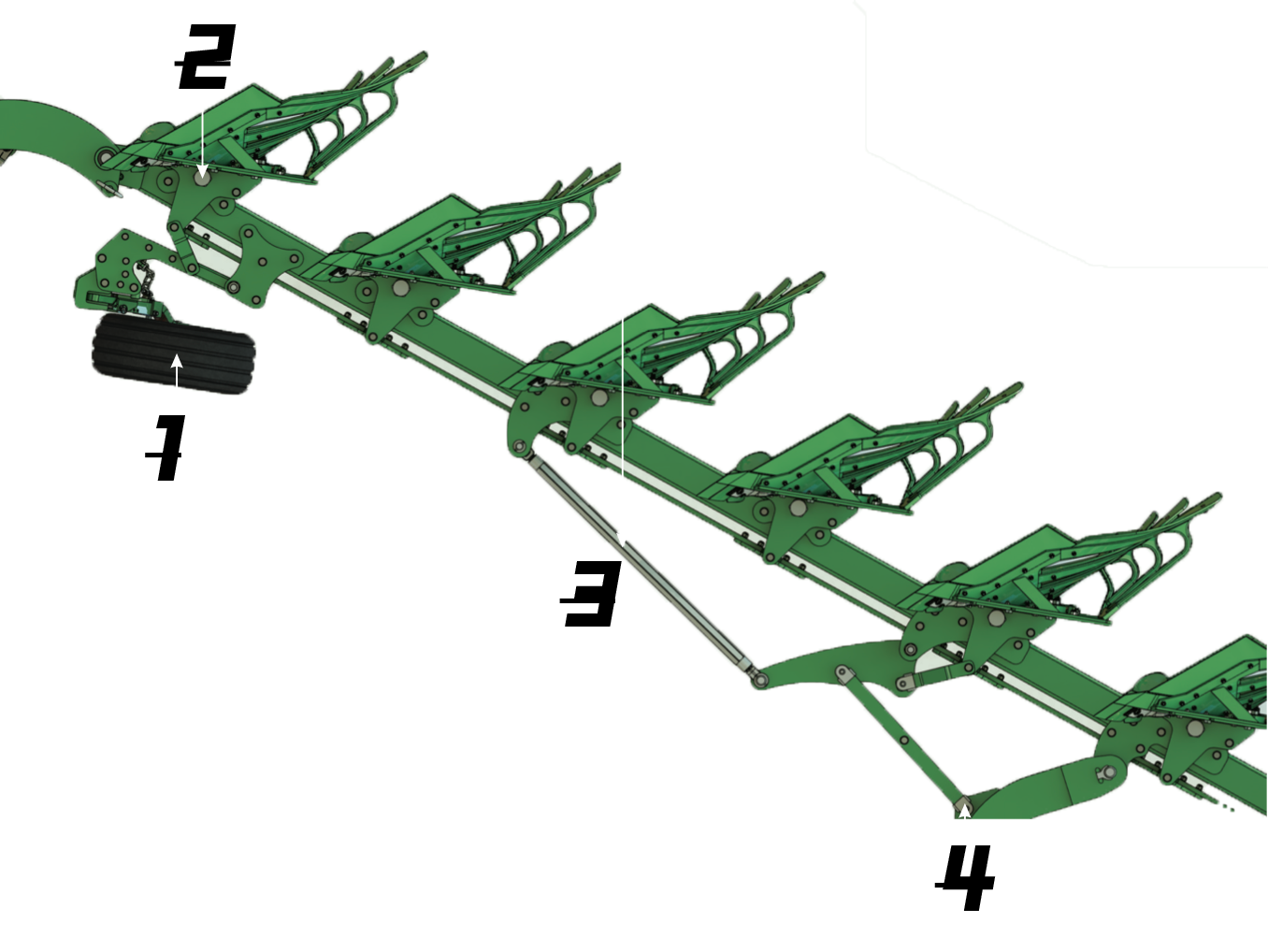

STRUCTURAL ANALYSIS

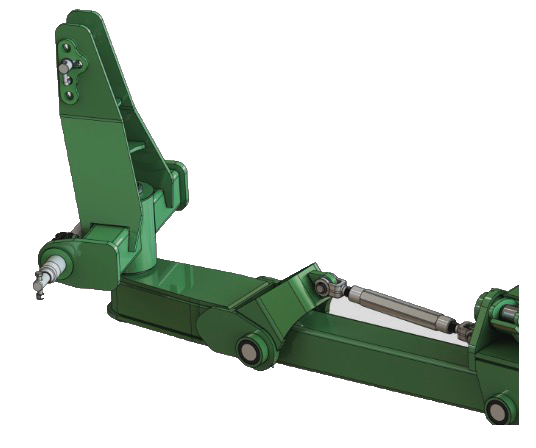

1.The distance between the reversible center and the rear axle of the tractor can be increased or reduced by rotating the plough head.

2.Good overloading protection by the safety shear bolt on main & auxiliary furrow.

3.Safety locking pins in two places, more safety after working mode change.

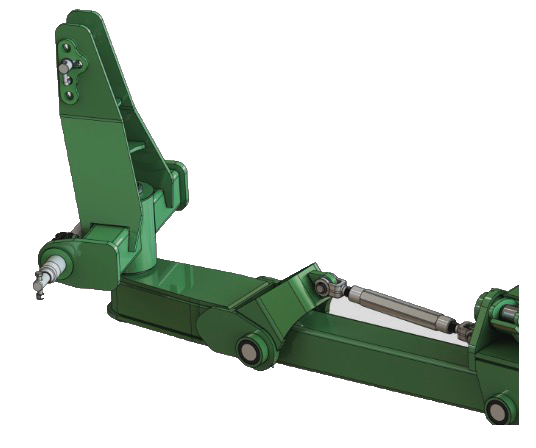

4.Adjusting the height of tractor traction point more accurately and conveniently by adjusting screw rod.

5.Easy to adjust the each furrow working width by automatic adjustment with hydraulic system or semiautomatic adjustment with unique design turnbuckle.

6.Anti-blocking type furrow support without choke by straw or plastic film, higher working efficiency and lower energy consumption.

7.Special treated spherical plain bearing with heavy roll extrusion for all main drive shafts, much longer service life and more reliable operation.

8.Under the ridge: used to adjust the pull rod for adjusting furrow working width. On the ridge: used to adjust the distance between the tractor and the edge of the furrow.The special turnbuckle can be replaced by hydraulic cylinder for better adjust performance in driver cabinet.

9.Adjust the angle of the plough main beam by using stop bolts on both sides.

10.Hydraulic Mechanical depth Adjustment device by using Throttle Valve system.

11.High tensile steel structure, more reliable and lighter.

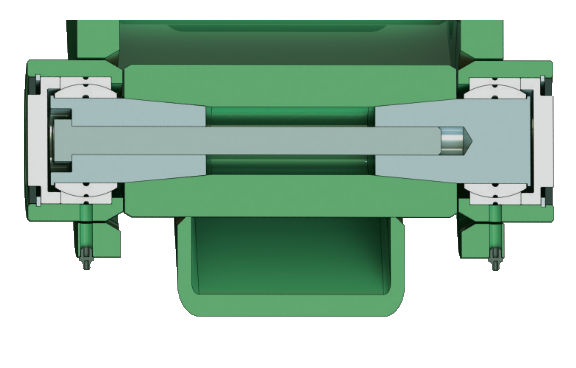

CORE COMPONENTS

1.4.The front and rear tires can be automatically changed the moving direction along with the change of width per furrow, which will increase much working efficiency in situations where the width of furrow operation needs to be adjusted frequently.

2.All rotating joints are sealed with high quality sealing parts and imported maintenance-free bearings for life-long lubricationfree maintenance.

3.Easy to adjust the each furrow working width by automatic adjustment with hydraulic system or semiautomatic adjustment with unique design turnbuckle.

Special treated spherical plain bearing with heavy roll extrusion for all main drive shafts, much longer service life and more reliable operation.

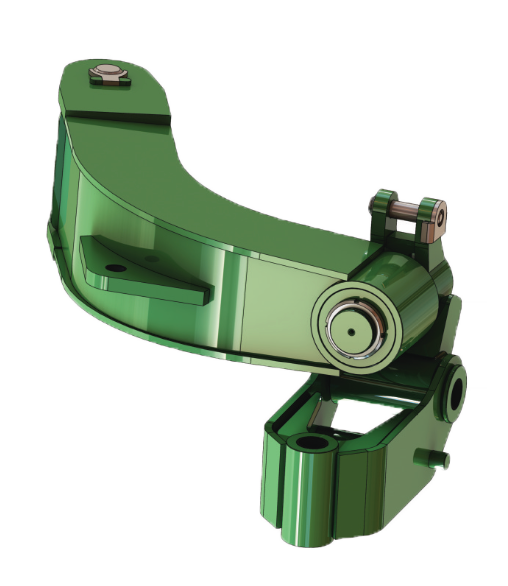

The height of the traction point is adjusted by adjusting thread rod, which make stepless and more efficient adjustment.

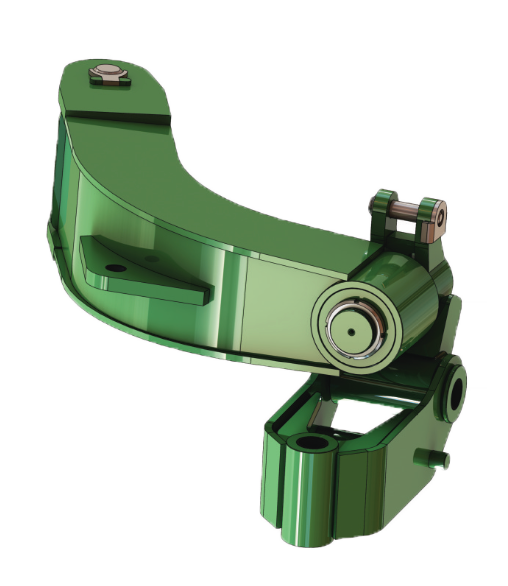

Reversible plough beam welded with special high tensile plate to ensure higher strength and better stability during working mode change.

The newly designed reversible arm joint with special material : higher strength and longer working life than that design by using casting.

Go to Top